*Image

above is for illustration

purpose only..

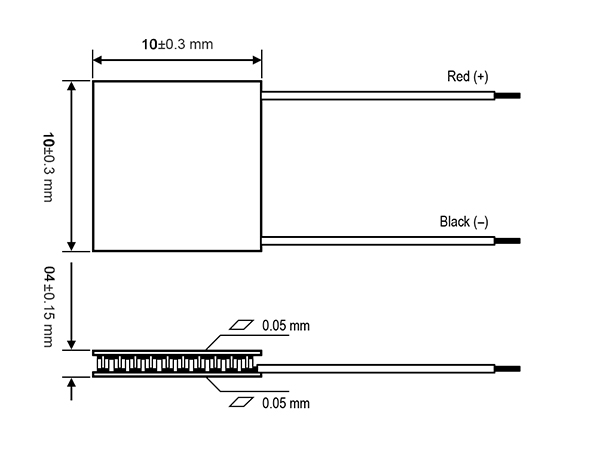

ATS-TEC10-47-012

TEC Module

Thermoelectric devices are semiconductor heat or refrigeration units which use the Peltier effect to create a heat flux between the two surfaces of the module. When a DC current is applied to the circuit, a thermoelectric module can work as a cooler or heater depending on the direction of current. A thermoelectric cooler (TEC), or solid state heat pump, transfers heat from one side of the device to the other side against the temperature gradient.

Features & Benefits

- High efficiency, high performance

- No sound or vibration

- Compact structure, small in size, light in weight

- Precise temperature control

- Environmentally friendly

- RoHS compliant

- Exceptionally reliable

Product Details

L=Length (mm);W=Width (mm); H=Height (mm);W (g)=Weight (g); Internal resistance (Ω)=Measured by AC 4-terminal method at 27°C; Imax=Maximum current at ΔTmax; Vmax=Maximum voltage at ΔTmax; Qmax=Maximum cooling capacity at Imax.,Vmax. and ΔT=0°C.;

ΔTmax=Maximum temperature difference at Imax.,Vmax. and Qmax=0 W;

| Part Number | Lifecycle

Status | Dimension (mm) | Weight

(gr) | Internal resistance (Ω) | Imax (A) | Vmax (V) | Qmax (W) | ΔTmax (℃) |

|---|

| L | W | H | Th=27℃ | Th=50℃ | Th=27℃ | Th=50℃ | Th=27℃ | Th=50℃ | Th=27℃ | Th=50℃ | Th=27℃ | Th=50℃ |

|---|

| ATS-TEC10-47-012 | ACTIVE | 10.3 | 10.3 | 4.7 | N/A | 0.16 | 1.77 | 4 | 4 | 0.8 | 0.94 | 2 | 2.23 | 68 | 73 |

Thermal Performance

| Schematic Image

|

*Image above is for illustration purpose only.

|

ATS-TEC10-47-012

(Data Sheet)

|

|

|

|

|

Complete Your Liquid Loop with ATS

ATS has the products needed to design a complete liquid cooling loop : iCDMs (Industrial Cooling Distribution Modules), Tubed and High Performance Cold Plates to transfer and remove the heat from the source; Heat Exchangers to transfer heat from the liquid to the air with or without a fan; Chillers to circulate and condition the fluid in the system, Compact Refrigeration Modules for very high capacity cooling. In addition , ATS offers Flow Meters to measure the volumetric flow rate of the fluid in the system and Leak Detectors to notify users of any leaks in the system.